Powder Coating Wheels – What Does It Take to Powder Coat Your Wheels?

Powder Coating Wheels – What Does It Take to Powder Coat Your Wheels?

If you're considering powder coating wheels or rims and you're located in Salt Lake County, Utah County, Davis County, Weber County, or Cache County, it's important to understand what goes into the process. At Full Blown Coatings, we regularly work with customers looking to restore, customize, or protect their wheels using powder coating and sand blasting services. From start to finish, the process is detailed and technical, but the results speak for themselves.

Why Powder Coat Your Wheels?

Durability and Protection

Powder coating offers one of the most durable finishes available for wheels. It resists:

- Chipping and scratching

- UV fading

- Corrosion from road salt and moisture

This makes it especially effective in Utah's variable weather, where summers can be harsh and winters are full of snow and salt-treated roads.

Aesthetic Customization

Whether you're into matte black, high gloss, textured finishes, or something unique, powder coating gives you flexibility. One customer from North Ogden brought in an old set of alloy wheels and requested a satin bronze finish. After coating, the rims looked completely transformed and helped give his entire vehicle a fresh, upgraded look.

Cost Savings Over Replacement

Instead of buying brand-new wheels, many customers choose to refinish their current ones with powder coating—achieving a "like new" appearance for a fraction of the cost.

The Powder Coating Process – Start to Finish

Step 1: Sand Blasting

Before anything else, we sand blast the wheels to remove existing paint, rust, and grime. This is essential for proper powder adhesion. We’ve seen several cases where wheels were coated without proper prep and started peeling within months. Sand blasting ensures a clean, etched surface that allows the powder to bond fully.

Step 2: Cleaning and Pre-Bake

After blasting, we thoroughly clean the wheels and pre-bake them. This step removes any remaining oils or gases from the metal, which can cause bubbles or pinholes during the curing process. We often explain to clients that this pre-bake is like "priming the oven" – it sets everything up for a perfect finish.

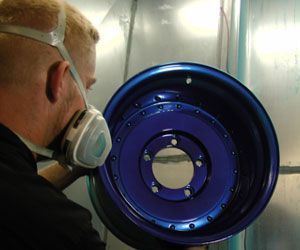

Step 3: Powder Application

Using an electrostatic gun, we apply dry powder particles to the prepped surface. Because of the electrical charge, the powder clings evenly to every contour, including complex spoke designs and hard-to-reach corners.

Step 4: Curing

The coated wheels are then placed in a curing oven, where they’re baked at around 375°F for 15 to 20 minutes. This step melts the powder into a smooth, continuous coating that is both beautiful and highly durable.

What Types of Wheels Can Be Powder Coated?

At Full Blown Coatings, we powder coat:

- Aluminum wheels

- Steel wheels

- Magnesium and forged wheels

- Custom aftermarket rims

- OEM factory wheels

Each material requires slightly different preparation, and we adjust our approach accordingly to avoid any warping or imperfections.

How Long Does Powder Coating Wheels Take?

Most wheel projects can be completed within 2 to 4 business days. The timeline depends on the initial condition of the wheels, the number of coats requested, and any specialty finishes. We offer expedited service when needed and communicate clearly about turnaround times.

A customer from Spanish Fork had a last-minute show coming up and needed a set of wheels done quickly in candy red. We pulled out all the stops and had them finished and ready to go in just three days.

What Does Powder Coating Wheels Cost?

The cost of powder coating wheels depends on:

- Wheel size (15", 17", 20", etc.)

- Condition and prep time needed

- Chosen color and finish (standard, metallic, two-tone, etc.)

On average, you can expect to pay less than half the cost of a new set of wheels while extending the life of your existing ones significantly.

Common Questions We Get

Can you powder coat over chrome? Yes, but it requires special prep. We must remove the chrome layer through chemical stripping or blasting before applying the powder.

How does powder coating compare to painting? Powder coating is more durable, eco-friendly, and longer-lasting than traditional wet paint. It also has fewer environmental risks due to no volatile organic compounds (VOCs).

Can you match factory wheel colors? Absolutely. We have a wide selection of stock and custom color options, and we can often match factory tones with amazing accuracy.

Is it safe for high-performance wheels? Yes. We’ve worked with racing enthusiasts and off-road drivers to powder coat performance wheels that see intense use and stress.

Full Blown Coatings: Your Local Powder Coating Experts

We proudly serve customers throughout:

- Salt Lake County

- Utah County

- Davis County

- Weber County

- Cache County

With years of experience and a fully equipped facility, Full Blown Coatings provides professional sand blasting and powder coating services under one roof. We treat each wheel with precision and care, ensuring your investment not only looks amazing but also stands the test of time.

Final Thoughts

Powder coating your wheels is a smart way to protect your investment, boost curb appeal, and extend the life of your vehicle components. But the quality of the result depends on the process.

At Full Blown Coatings, we don’t skip steps. From sand blasting to final cure, your wheels receive the attention and expertise they deserve.

Have a set of wheels in mind? Contact us today for a free consultation or drop by our shop to see our work in person.